This is what the factory uses for all of the brake lines. Steel is affordable durable and easy.

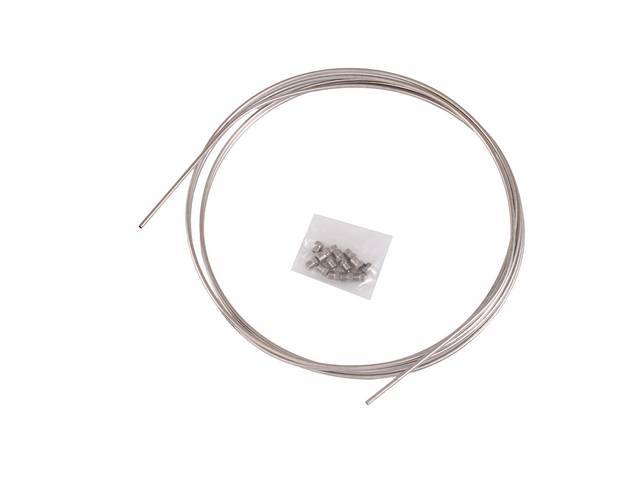

3 16in Brake Line Coil Steel 25ft All48040

How to coil brake line. Joined aug 16 2009 messages 1774 location lakewood nov 7 2015 2 i believe the coils are designed to relieve stress from vibrations and body movement. To learn more about how different types of braking systems work check out the links below. Order brake lines domestic for your vehicle and pick it up in storemake your purchase find a store near you and get directions. Each has its benefits and drawbacks. As well the coil can be scrunched together on the brake line while bending to prevent the line from kinking. Those coils up front do nothing to assist with those.

Check here for special coupons and promotions. The brake lines for front and rear both coil after leaving the master cylinder. Back at the rear end when it articulates which is why theres a flex line. Front brakes which is why there are flex lines. Steel soft steel stainless steel and nickel copper alloy. Why does it do that and when i make new lines do i need to include them.

Steel the most common type of hard line is galvanized mild steel. Your order may be eligible for ship to home and shipping is free on all online orders of 3500. There are four types of hard line used for braking systems. By forming the brake line into a coil the flexing in any one section is very small and so puts almost no strain on the line. The hard line deflection is most likely to happen in the center of the body in a perimeter frame or a unibody car without a chassis under it. While this wrapping may at some point provide protection from an impact the likelihood of such an impact is fairly remote.