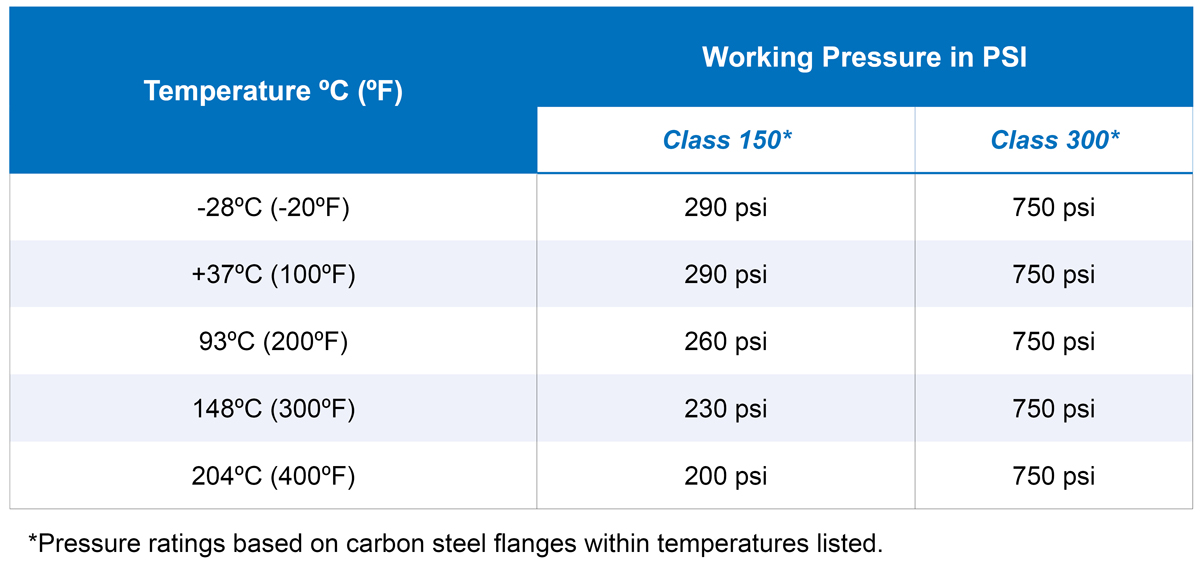

Tapered pipe threads npt do not have a specified torque rating. Fluids piping and hydraulic design data.

Pipe Thread Types And Designations Pdf Free Download

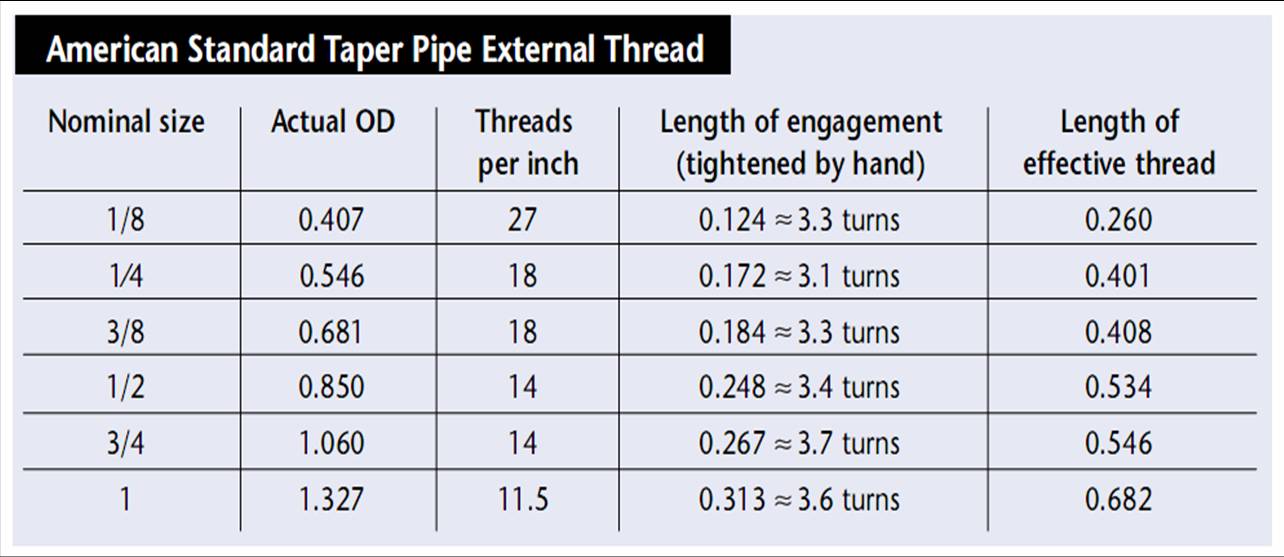

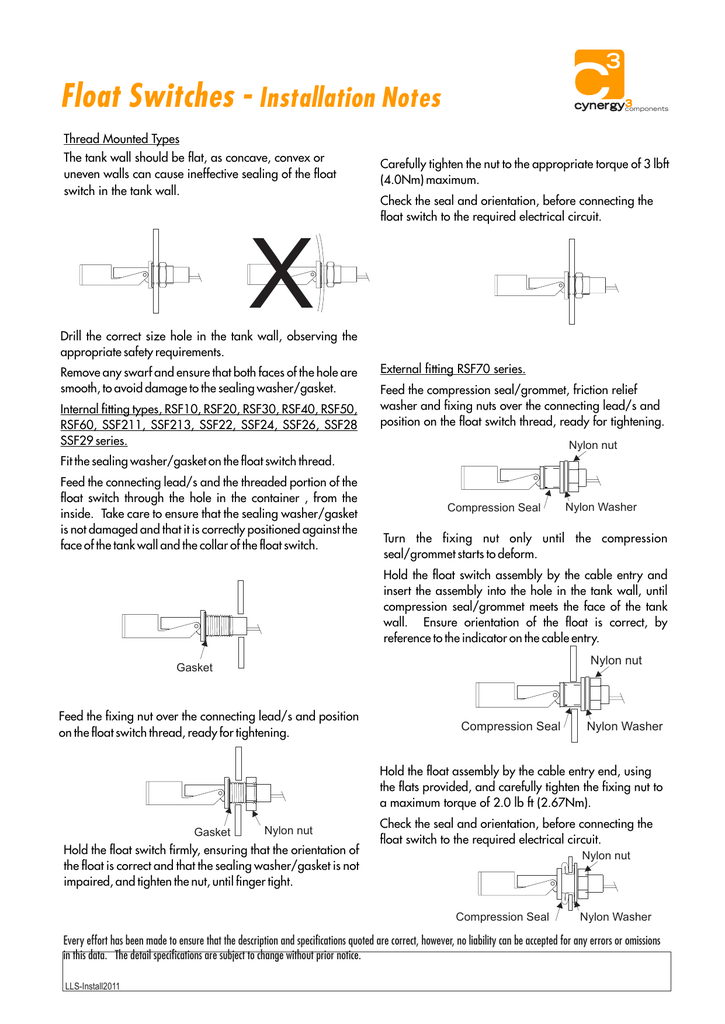

Npt thread tightening torque. Assembly torque adapter unions and pipe fittings. Npt is a letter designation for american standard pipe taper thread. For mixed metals use the torque of the lower of the two metals torque range is normally calculated 10. Traditionally they are tightened by technicians until they seal. For brass use 70 of the torque value of steel. Failure to reach minimum engagement usually indi cates poorly formed or damaged threads.

Tfft assembly turns from finger tight with pipe thread sealant or teflon tape applied. 34 npt use 34 wraps. Prepared fittings should engage about 2 turns by hand and at least 56 turns before reaching the recommended torque. For shape fittings approximately 12 turns should be made and then torque to the desired orientation without exceeding maximum recommended torque. For stainless steel use the high value of the torque range of steel. Liquid pipe sealant containing no teflon is the only pipe sealant recommended.

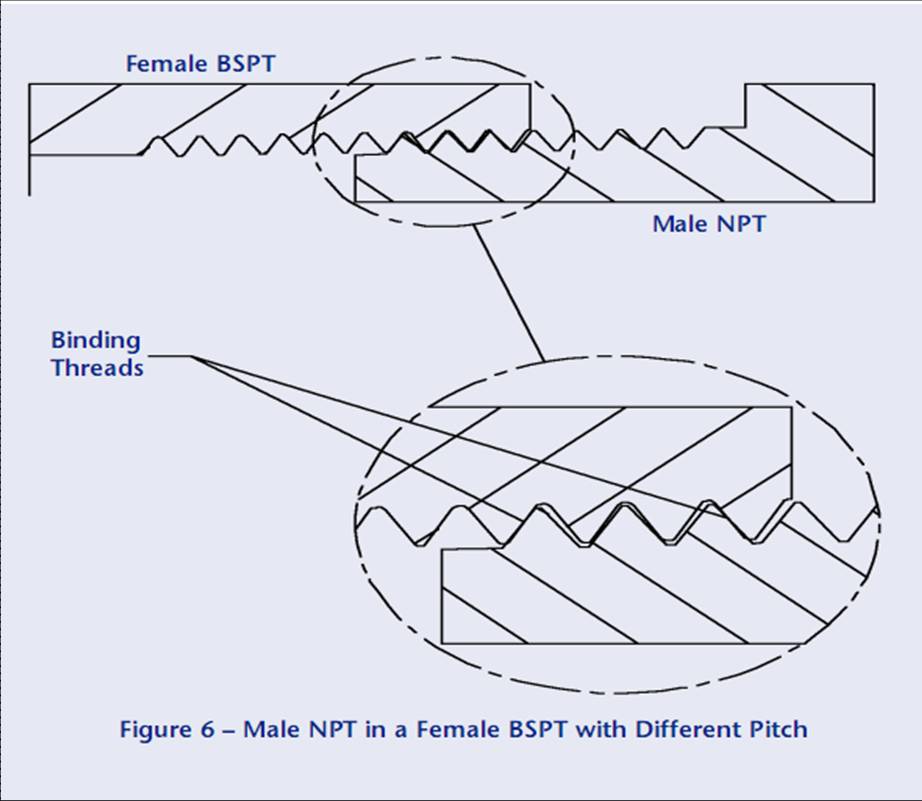

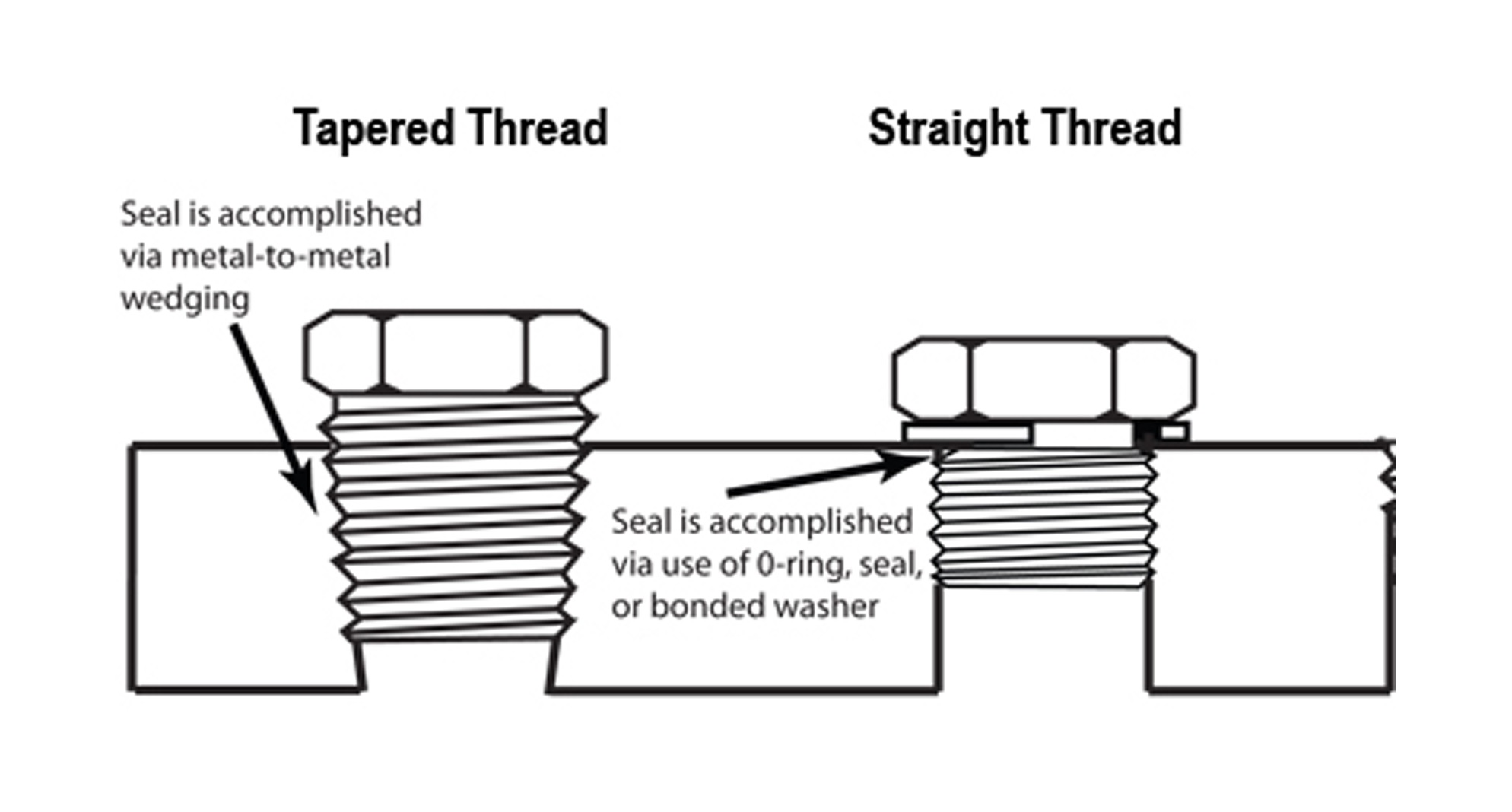

Npt pipe threads have a taper cut into the male and female fittings. The tensile stress created by tightening the fitting beyond hand tight and 1 or 2 more turns will crack the female fittings. For tapered pipe onlyl. Never use teflon tape. Pipe thread installation torque table chart. With zinc plating always lubricate threads and seals.

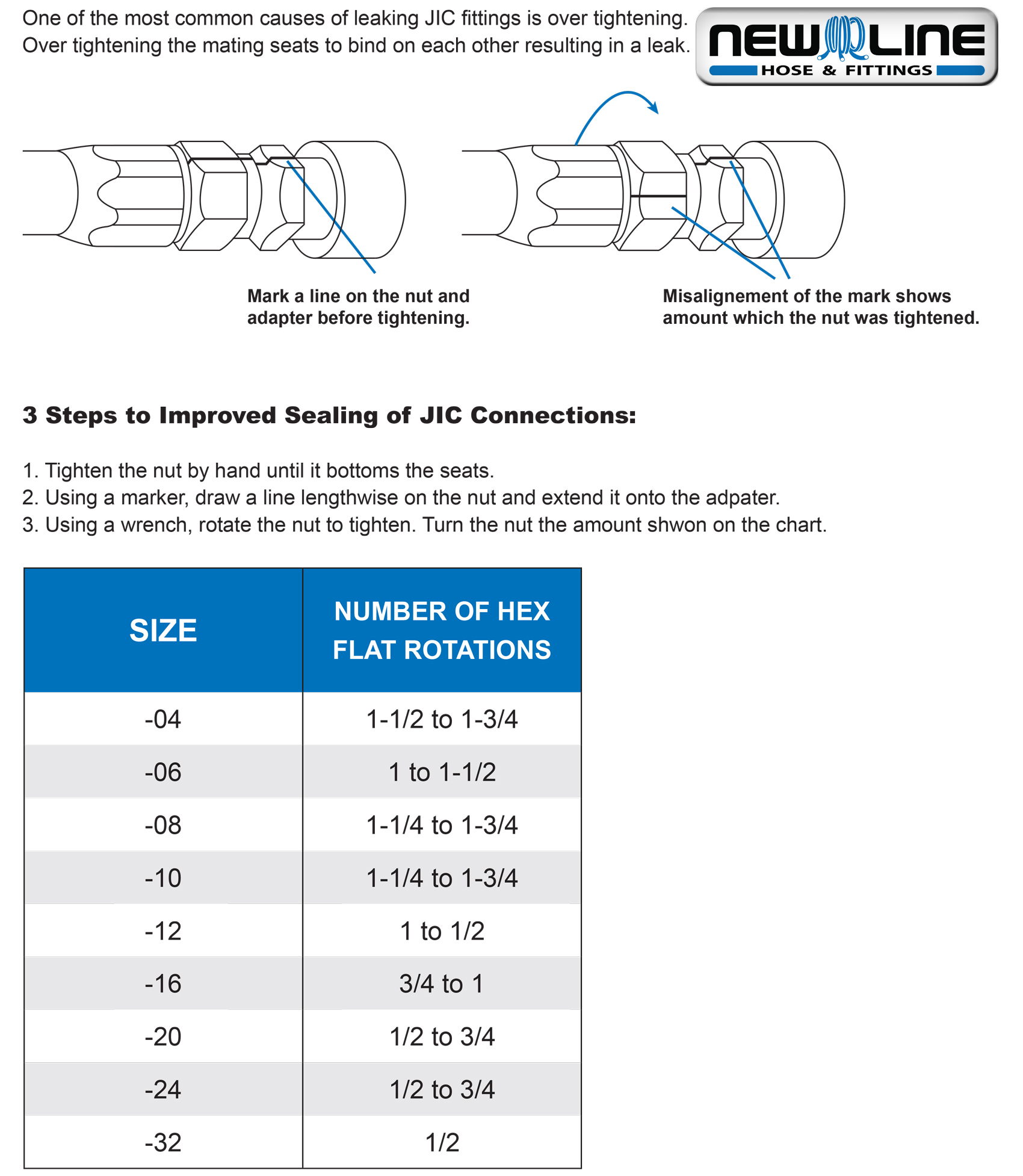

Brass and steel pipe thread npt installation procedure and torque specification table and chart. Torque recommendations below are for valve connected to a. How tight do you have to tighten national pipe thread. Torque values for installing steel or malleable iron pipe plugs or fittings with pre applied loctite 516 banding are given belowall threaded connections should be lubricated before assembly. That typically means wrench tight plus a little more. Wrench tighten the valve to the turns past finger tight values shown in the table below.

In many assemblies a sealant is placed over the male pipe threads to aid in sealing the joint. More turns will put to much pressure on the fitting and may crack it and cause a leak. Thread size recommended torque 116 npt 45 nm 34 ft lb 18 npt 2023 nm 1517 ft lb 14 npt 2429 nm 1821 ft lb 38 npt 2734 nm 2025 ft lb. For straight fittings tighten to recommended torque listed in the following table. Never back off loosen pipe threaded connectors to achieve alignment. These specifications are for carbon steel.

The taper placed on both sets of threads allows for a solid mechanical joint that does not leak liquid or gas. They should be hand tightened and then another 1 or 2 turns but no more. This ambiguous guideline is a frustrating if you are developing a procedure for the mass production of npt connections. Screw the valve into the mating port or fitting to the finger tight position.