For the purposes of this article we will focus on just three common rubber types found in o rings and similar automotive seals. O ring material family chemical compatibility temperature resistance and other properties all factor in to o ring material selection for an application.

Details About O Rings Rubber Seal Thickness 1 5 2 2 5 3 1 8 2 65mm Nbr Sealing O Rings

Nbr o ring material. For general purpose applications such as pneumatics hydraulics and fuel systems nitrile o rings provide cost effective sealing performance especially when hydrogenated versions or specialty material compounds are used. We offer o ring materials in custom and industry standard sizes. Kootans nitrile rubber o ring kit o rings assortment kit set 24sizes 1200pcs oil resistant nbr metric o ring sealing assortment kit for air plumbing fuel jnjector and faucet seal o rings 42 out of 5 stars 39. Note that each type is actually a family of rubber compounds. Silicone and kalrez o ring materials are also widely used especially in high temperature applications. Some of the common types of o ring materials include ptfe nitrile buna neoprene epdm rubber and fluorocarbon viton.

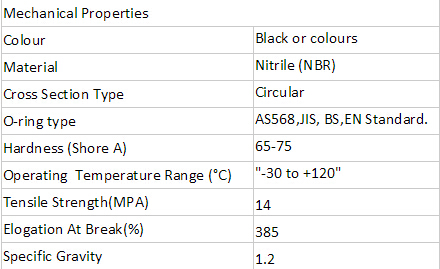

The term buna n is really not much more specific than the term steel. Nbr nitrile chemically is a copolymer of butadiene and acrylonitrile. Nitrile o rings also known as buna n o rings or nbr o rings are one of the most common types of o ring materials because of their low cost performance in basic water oils fuels and lubricants. As the nbr content increases resistance to petroleum base oils and hydrocarbon fuels increases but low temperature flexibility decreases. The nitrile o ring is commonly referred to as a buna o ring or nbr o rings. Datwyler offers a complete selection of both the standard as568 o ring and metric o ring sizes.

Nitrile provides excellent compression set tear and abrasion resistance. Buna n viton and epdm. The guide includes generalized recommended o ring mateiral uses and non recommended uses with typical material mechanical properties. Also called nbr or buna n nitrile o rings are probably the most economical and widely used elastomer out there. This material has a desirable set of properties including low compression set high resistance to abrasion and good tensile strength. Effective from 40c to 120c.

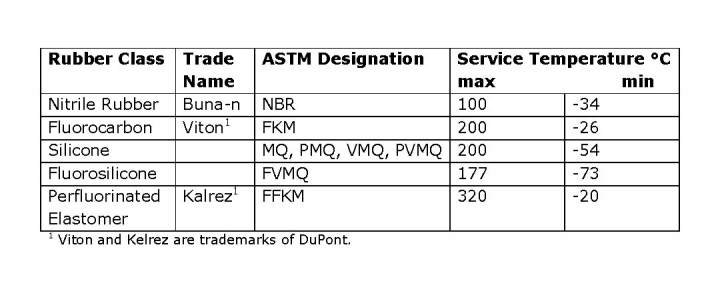

Nitrile rubber nbr o rings also known as buna n are one of the most commonly used sealing elastomers due to resistance to petroleum based fuels and lubricants and its relatively low price. Nitrile elastomers are copolymers of acrylonitrile and butadiene. Buna n o rings buna n o rings. This popular o ring material family comparison shows basic rubber material family properties and performance plastic properties. Acrylonitrile content varies in commercial products from 18 to 50. Buna n o rings also referred to as nbr o rings and nitrile o rings are the most widely used o ring material in the word because of low cost good mechanical performance with resistance to water most basic oils lubricants and some fuels many pneumatic hydraulic systems and the default choice for basic applications.

O ring material quick reference guide rubber sealing materials. There are a number of common variations of nitrile compounds.

Gallery of Nbr O Ring Material