Unplug the coil wire from the distributor to prevent the engine from firing while testing. Disable fuel injection by pulling the fuel.

How To Do A Diy Two Stroke Leak Down Test Diy Moto Fix

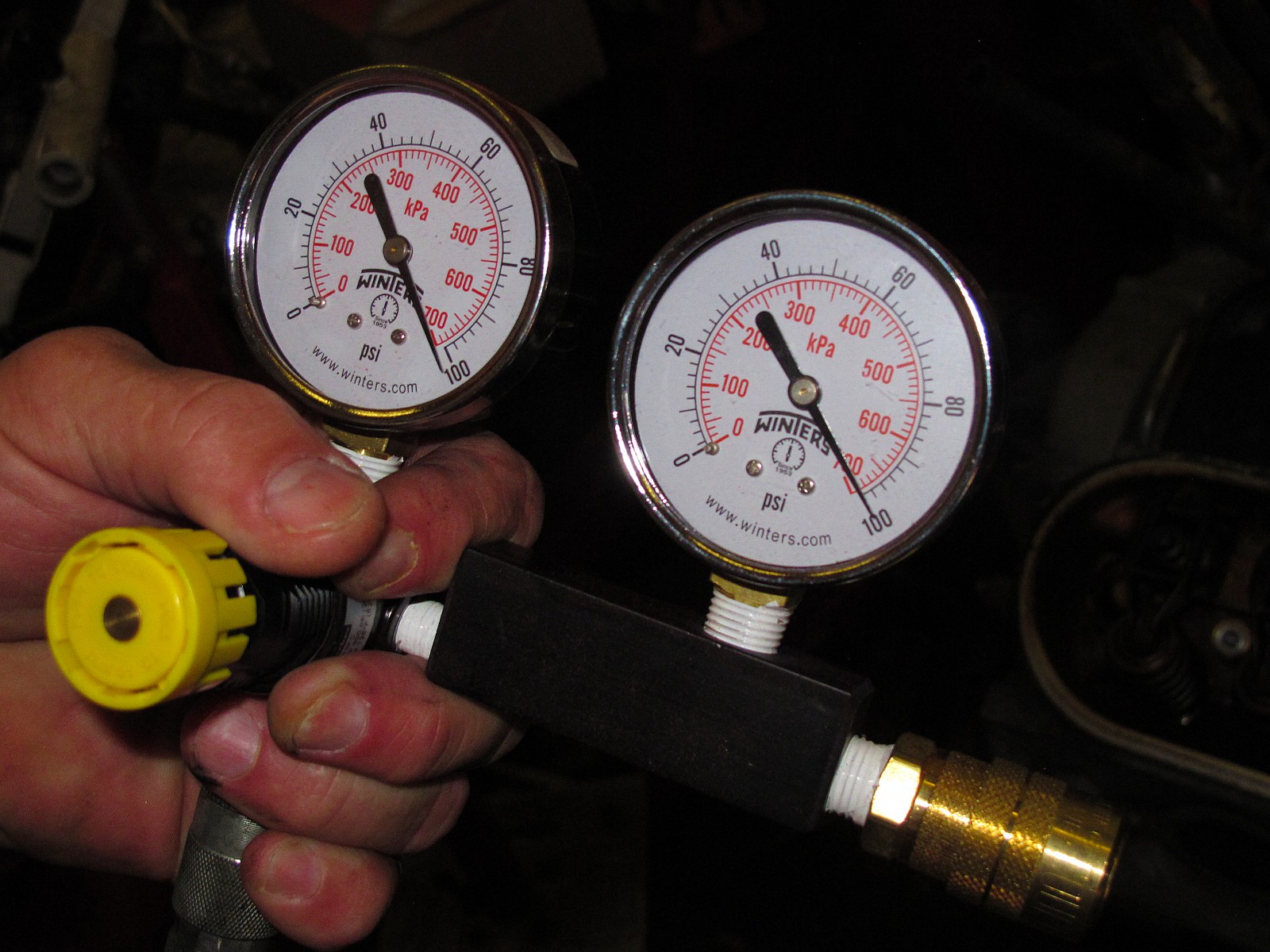

Leak down test diesel. One gauge on the tester measures the pressure of the air entering the cylinder and the other measures the percentage of the air escaping or leaking from the cylinder. An engine leakdown test is a compression test in reverse. Compressed air 80 to 90 psi is then fed into the cylinder. The tester then measures the volume of air needed to maintain a predetermined pressure in the cylinder. Test the engine at operating temperature for the best results. 10 millimeters and 14 millimeters thread adapters dual 2 12 inch chrome bezel gauges and rugged protective outer shell pressure regulated manifold with quick couplers and all comes with an easy to open blow molded hard case for storage.

The crankshaft is then turned so that each piston is at top dead centre. A cylinder leak down test requires the removal of all the spark plugs. Leak down tests on diesels in aircraft the leak down test is used because you dont want to stand next to a spinning prop doing a compression test. The performance tool w89729 leak down test kit can quickly diagnose internal engine problems such as bad rings valves and leaking head gaskets. Instead of measuring the engines ability to create pressure compressed air is introduced into the cylinder through the spark plug hole. A threaded coupling is screwed into a spark plug hole.

In a cylinder leak down test the engine is placed on tdc of the cylinder in question. Pressurized air is supplied to each cylinder and in moments displays a rate of leakage measure from 0 to 100. Then using a similar type of connector as the compression test we fill the cylinder with pressure. This cylinder leak down tester gauges leak down tests more accurately than standard compression tests. In the leak down test you move the up to tdc because of cylinder choke then work the prop back and forth to seat the rings.