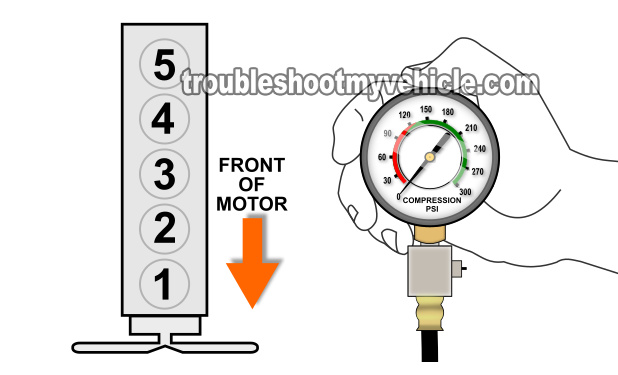

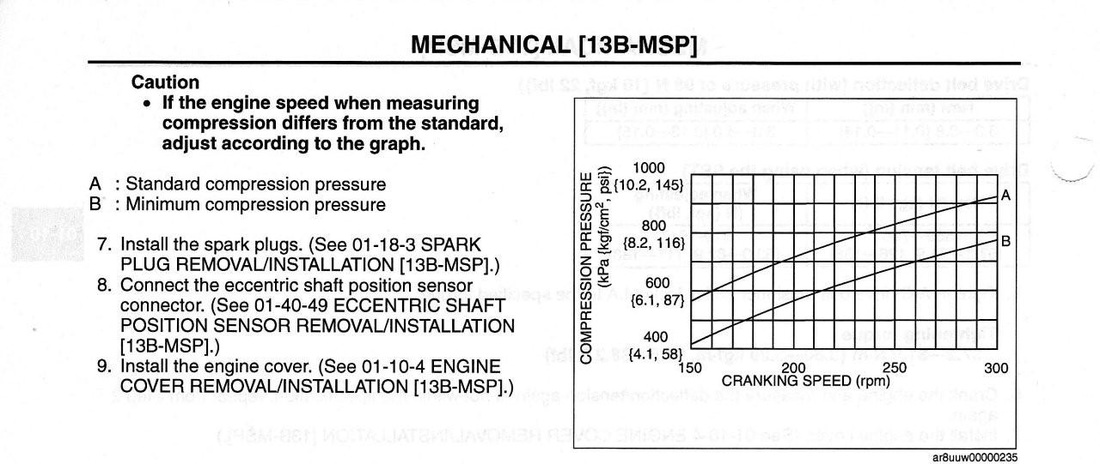

The needle on the compression gauge will stay at the highest indicated compression reading. Youll need to remove the spark plugs while the engine is warmed for.

Engine Compression Tester Gauge Kit

How to check engine compression. Put the compression test adapter into the engines first cylinder. The next step depends on the type of distributor you have. Step 3 turn the ignition on depress the throttle and crank the engine four revolutions. Pull the big wire that leads to the coil from the. Step 1 remove the fuel pump and fuel injection fuses. If youre testing a diesel engine make sure youre.

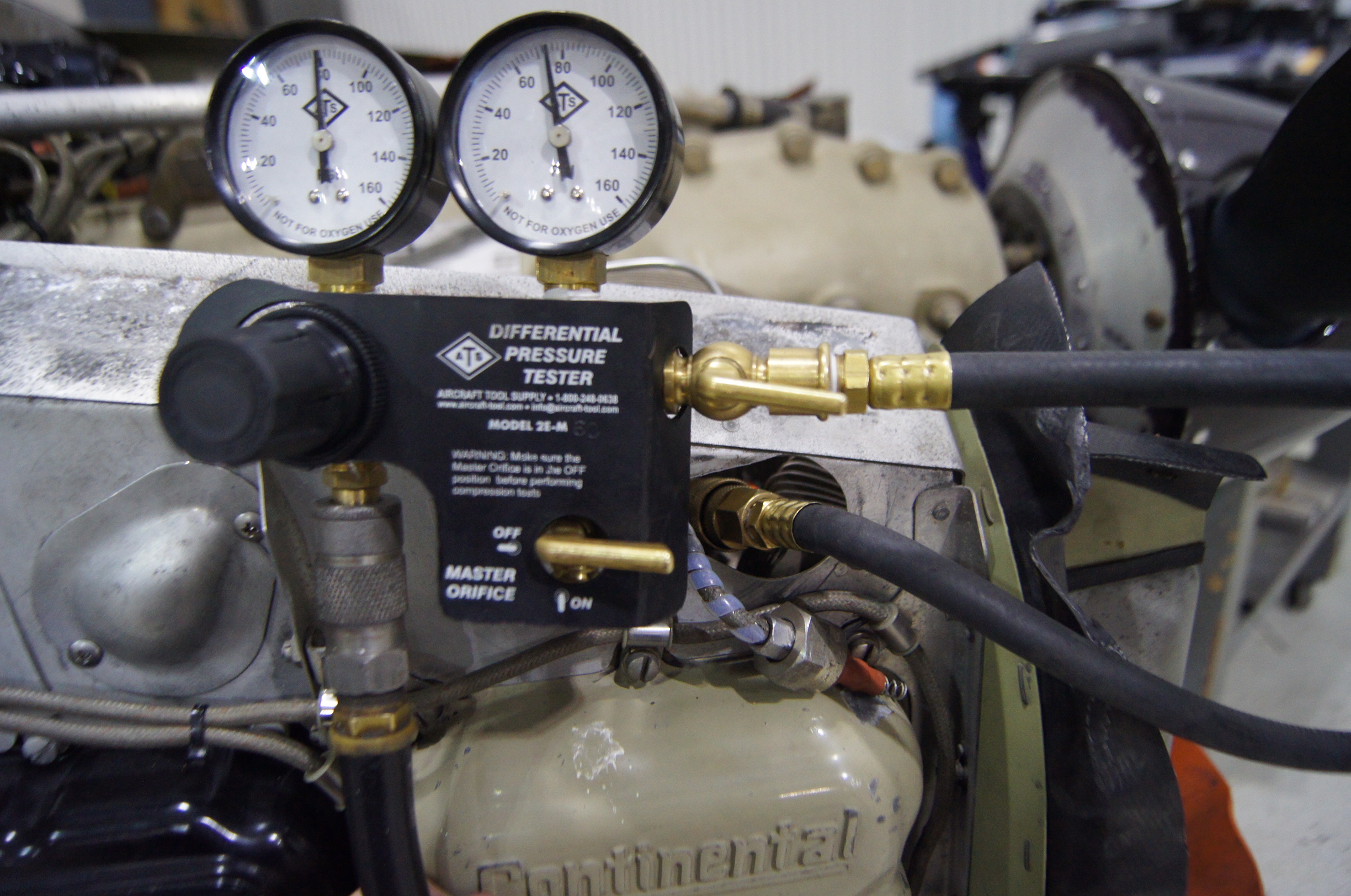

Disconnect the main wire to the coil and spark plug wires. How to do a compression test engine cylinder compression test guide. Consider doing a compression test. This number indicates the compression for that cylinder only. A cars engine needs cylinder compression to run correctly. If your engine is running rough or is lacking power.

Crank the engine at least 4 times to. It is important to perform a compression test every time a tune up is done as part of preventative maintenance. Performing the test 1. Preparing for the compression test. How to do an engine compression test i. Double check that you disconnected the appropriate stuff so the engine doesnt actually start.

Compression test service costs. On vehicles with distributors. A compression test is a good way to measure the condition of the rings cylinders and valves. Now turn the key and crank the engine over for about 10 seconds. Heres how to use a compression gauge. Connect the compression gauge to the opposite end of the hose.

Once you install the compression gauge youre ready to start your test. When having a compression test done by a repair shop the costs will vary depending on. Ask a helper to. Have someone sit in the drivers seat with the engine off the gearshift in park or neutral and the parking brake on. Step 2 start the threaded end of the compression gauge in a spark plug hole by hand. Look down on the engine to figure out which.