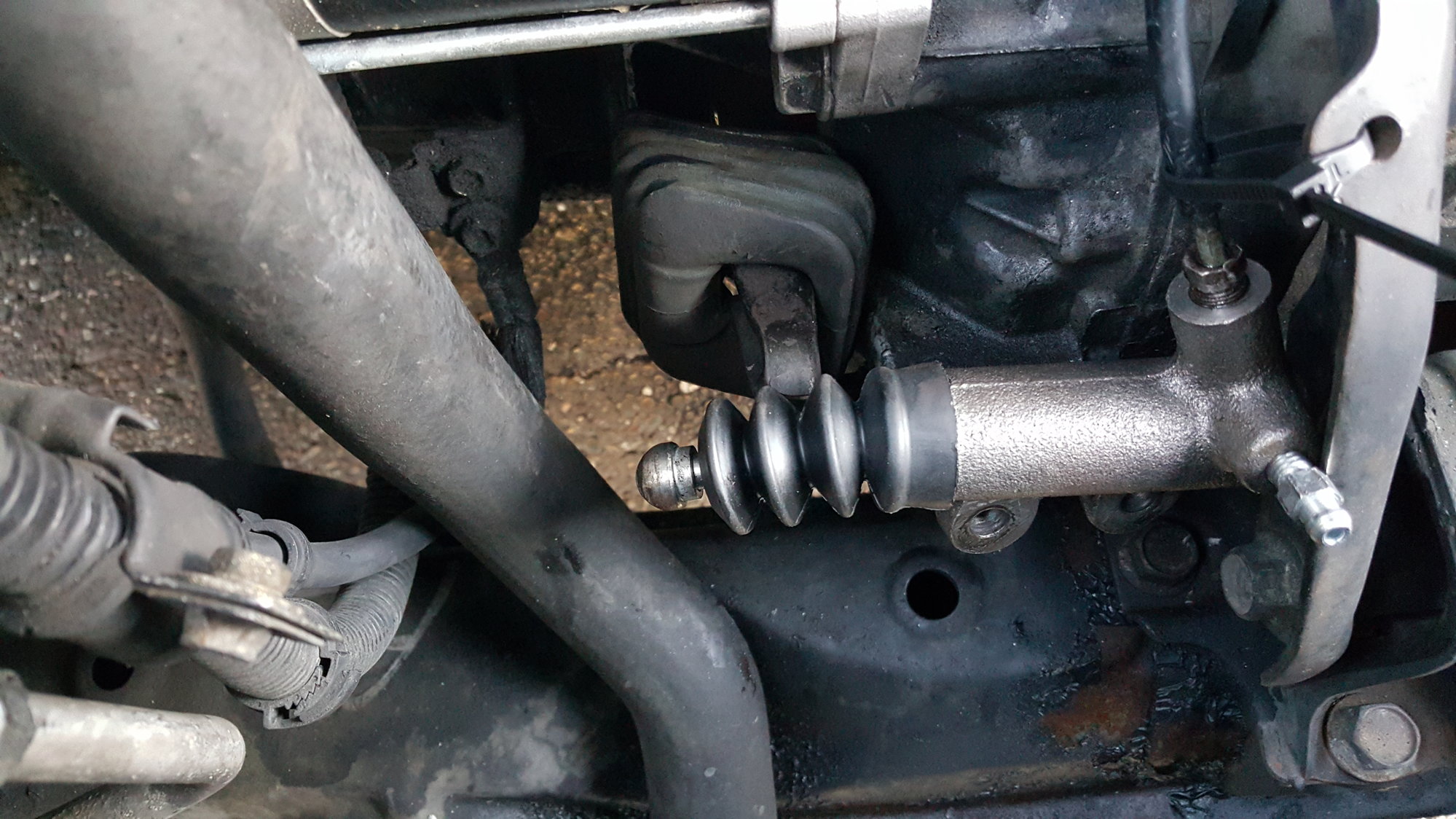

Mcleod rxt clutch new oem clutch cable steeda quick release quadrant lakewood adjustable pivot ball anti venom mod amsoil manual transmission fluid syncromesh 4 qts i resurfaced my stock flywheel. The linkage rod adjusts where the clutch engagement is at.

Clutch Fork Adjustment Problem

Clutch pivot ball adjustment. Learn how to measure the flywheel and do the math. Setting the length of the pivot ball to this dimension should get you in the ballpark. I like having the clutch start to release about two inches from the floor. Lakewood clutch pivot ball allows additional adjustment of the clutch fork height. Measure the distance from the face of the bellhousing where the transmission mounts to the part of the throw out bearing that the release arm pushes against. Then depress the clutch pedal fully and release it.

Ive found the adjustable pivot has a maximum length of about 18 inches. Jegs clutch adjustment rod and swivel. This black oxide adjustable steel ball is recommended for use with lakewoods safety bellhousing. Lakewood recommends these for all of their bellhousings. With this setup i adjusted my pivot ball 45 mm shorter than the stock pivot ball. There needs to be about 14 play between them.

This pivot ball fits chevy pontiac olds most applications. How to properly adjust the fork clutch pivot ball height to achieve the proper clutch fork geometry. Jegs gm clutch pivot ball bracket for cars and pick ups short style 6155 jegs clutch pivot ball stud most 1963 80 gm. If your flywheel is different than the 960 stock dimension move the stud again towards the block the amount thinner the flywheel is or away from the block if the flywheel is thicker. Lakewood clutch fork pivot balls allow for additional adjustment of the clutch fork height when the clutch assembly is changed. 1349 1349 lowest price guarantee.

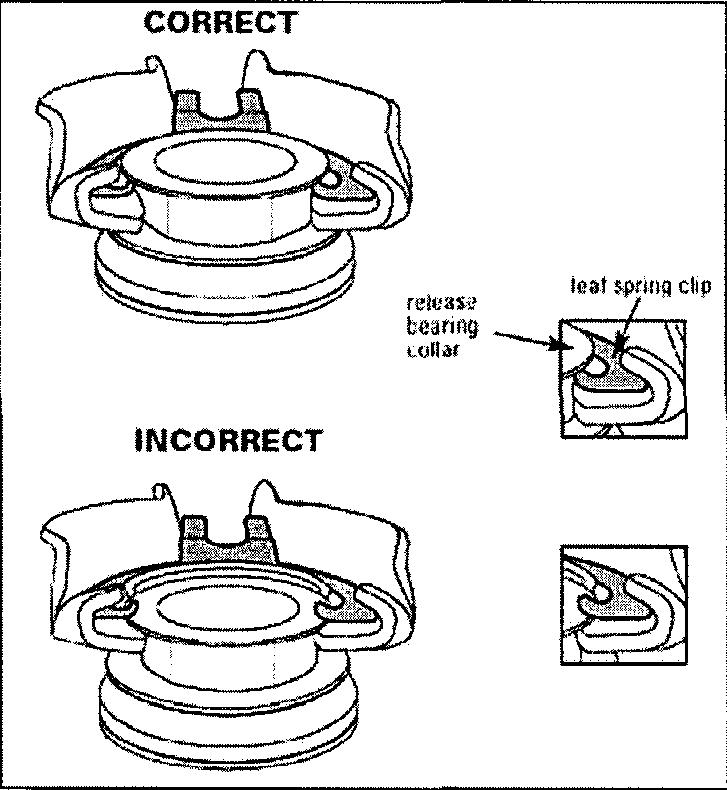

The purpose of the adjustable pivot ball is so you can get the throwout bearing away from the pressure plate. 1282 jegs clutch adjustment rod 4 34 long. Itll be simple adjust your stud until it is 4750 from the front of the bellhousing. Check the width of the contact pattern the fork makes on the bearing then adjust your pivot ball so that width is centered about an imaginary vertical line through the center of the bearing. At least thats the way i would do it. Helps eliminate release problems when installing a high performance clutch.

If running a block plate adjust the stud out towards the block for the thickness of the plate. Jegs clutch pivot ball studs.