Need some advice on tightening down ball joints and tie rod ends. We cannot take back used parts.

How To Replace The Lower Ball Joint On An 03 07 Honda

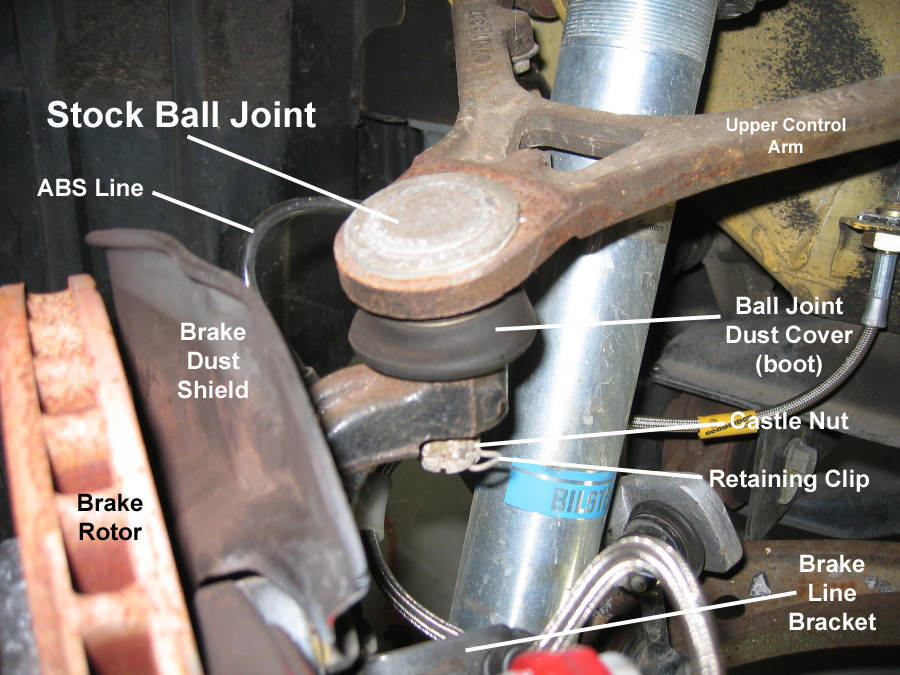

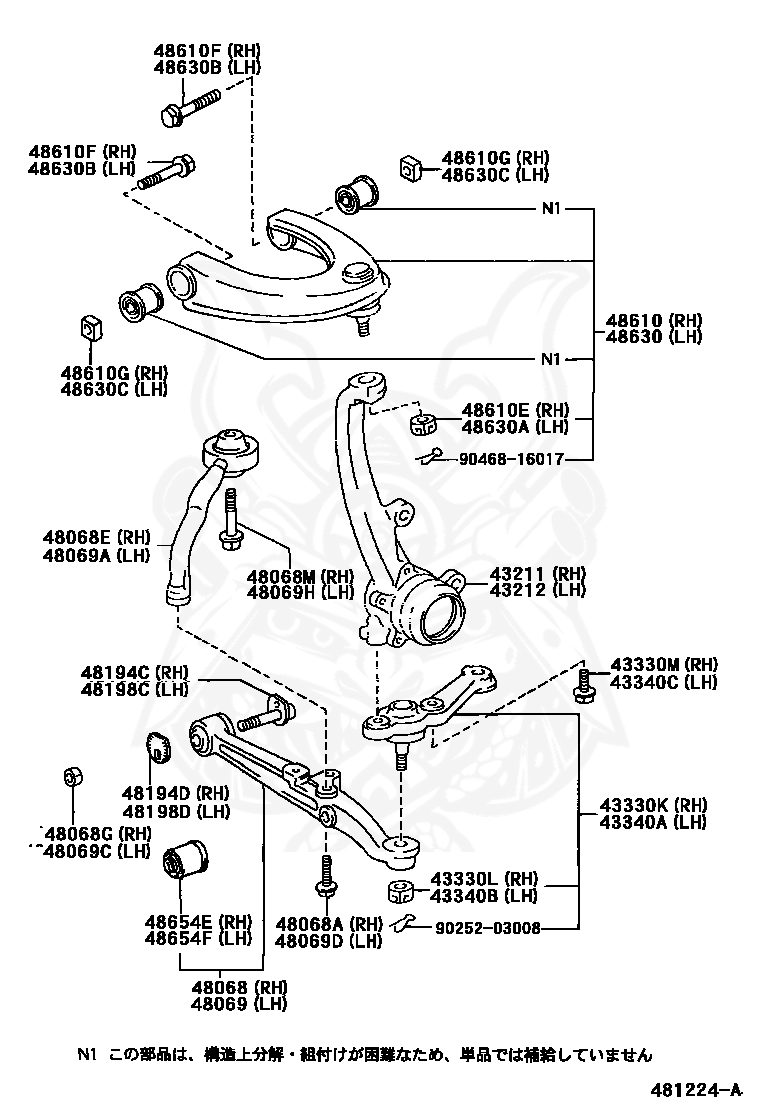

Ball joint castle nut. There was no play but i noticed something odd when i was looking around. Need a socket to get the castle nut off it is 34mm got it removed. A ball with a threaded stud a socket and a rubber boot. The upper ball joint requires 150lbft 170lbft for tightening the slotted nut. Im working on a car where my replacement ball joint nut tightens down below the cotter pin hole. Ball joint castle nut sizes 05 19 03 0512 am post 232282 in response to chev58ss hi 58ss the replacement joints are 12 20 unf and the nut size is 34.

The upper ball joints castle nut is screwed in so far that the cotter pin is completely under it rather than going through the castle nut. The ball joint also serves as a connection point for your steering knuckle wheel and the rest of your suspension. The torque load as described in these pages is essential for the lower and shock ball joint the suggested torque for tighten the lower ball joint to its housing is 250 lbft 300 lbft as you mentioned enormous torque. It seems like it should still retain the nut fine but it just seems wrong. Steering knuckle arm and ball joint maintenance m1009. Most of the time.

The ball and socket allows your suspension to move at different angles for steering and going over rough spots or bumps. In the unlikely event that a part has been placed on backorder or discontinued we will do our best to try and find one for you as quickly as possible. The uppers use a castle nut with a cotter pin. Similar issue to the jl wrangler. The lowers and the uppers are the same thread size but the lowers use a regular nut and star type lockwasher. Genuine toyota scion parts.

Heard a creak click when cornering slowly on my gladiator le. Hope this helps you out. The upper ball joint castle nut is tqd 50 90 lbs per manual specs and the cotter pin goes through where it is supposed to go as in hole and slot. We cannot take back installed or tried parts. Most of the time you torque the nut down insert the cotter pin and then bend the pin around the castle nut so it wont work loose. The lower ball joint castle nut is tqd the same but the cotter pin is way high and does not go through the castle nut and hole together.

Checked both front lower ball joints both castle nuts were finger tight torqued from the factory. A ball joint consists of three pieces.