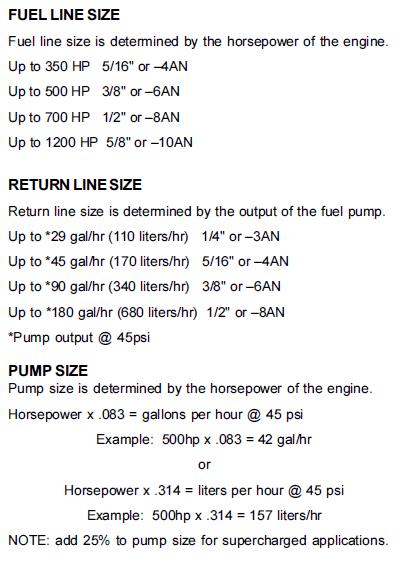

The fuel line along with the other parts of a fuel system are responsible for delivering the fuel from the fuel cell into the carburetor. A liter of fuel weighs about 16 lbs.

Understanding Fuel Line Fittings Straight Thread And An

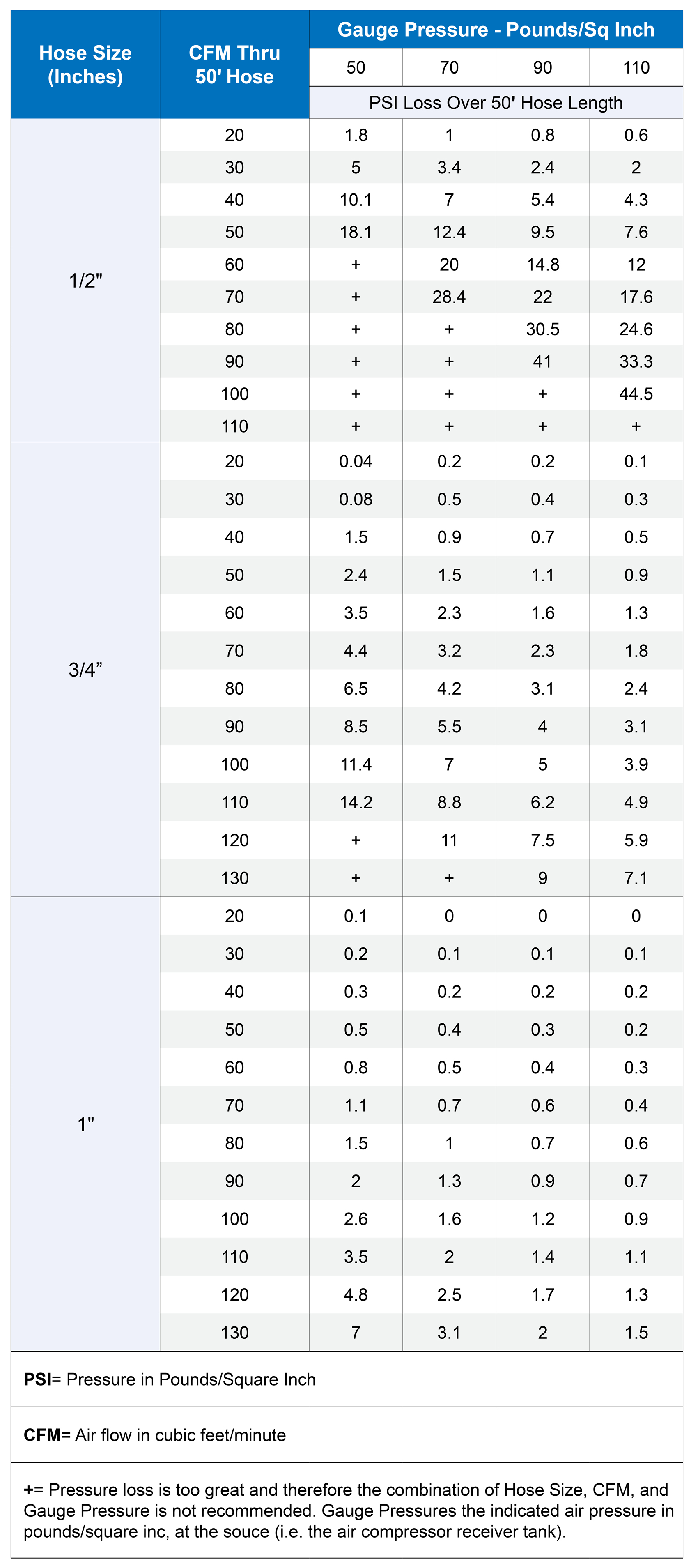

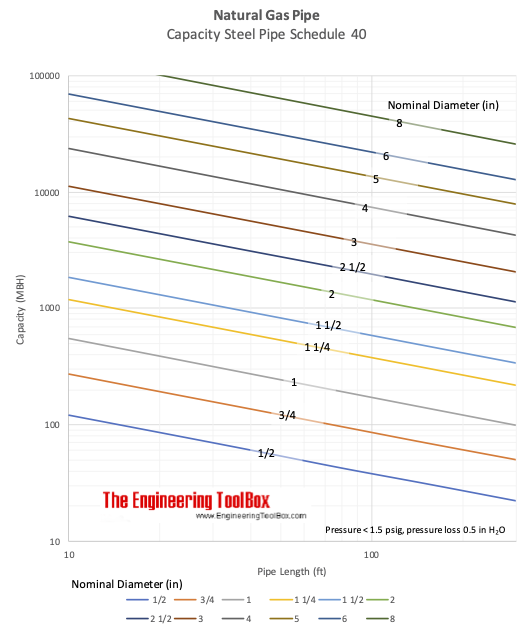

An fuel line size chart. An fittings hose and tubing size reference charts. In order to plumb your vehicle with a minimum amount of time effort and money you should know the basics about hose hose ends and adapter fittings. The size of the fuel line is determined by the outside diameter. Will increasing the line size to ½ help. If you are using an existing gas line you must take into consideration the existing gas line capacities to ensure you will have proper pressure. Hose diameters are assigned an numbers.

Using your automotive hose size choose from the chart below to find the an equivalent for hose hose ends and adapter fittings. Stainless tubing an equivalent all dimensions are in inches unless otherwise noted. It is important to have the right size so the vehicle operates efficiently. Tube size od thread size wrench size 2. Sizes for rigid tubes were already standardized with sizes called out by tubing od 316 12 etc. Tapered thread tapered thread also known as pipe thread typically uses a 2 angle on the threads instead of running parallel.

Npsc american standard straight coupling pipe thread are the standards for straight thread in the us. Completing the measurement is simple and takes relatively few tools. You need the minimum flow rate at your fuel systems operating pressure. An hose sizes were designed to match the id sizes of these rigid tubes. Fuel injection will usually be between 35 65 psi. To get lph divide lbshr.

Fuel pumps are usually advertised by their. This chart is for reference only we recommend you consult with a licensed plumbergas fitter or nfpa54 national fuel gas code current edition for more details. Yes the pressure drop thru a ½ line is a nominal 5 feet versus 35 feet for the 38 id fuel line. The idea behind an hoses and an fittings was to provide a flexible alternative to rigid tubing in plumbing systems on aircraft and military vehicles. For carburetors this is between 4 75 psi. By john heard last updated dec 31 2014.

Pipe sizing charts a reference chart for propane tank pipe sizes it is best to always consult a qualified and certified technician to advise on the best piping that is needed for your propane tank to properly fuel your appliancesprovided here is a guide for more information for you to refer to. The ½ line will result in a ½ pound drop versus the 3 pound drop for the 38 line at the stated flow of 833 gph enough to support 1000 hp at a bsfc of 5. 16 15625 lph. Can you see the confusion starting. What you need to know about copper piping with your propane tank. This allows the threads to interfere and seal off.